10 Best Deck Screws 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

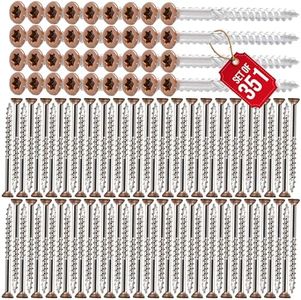

Our Top Picks

Winner

Hillman 967777 Premium Outdoor Wood and Deck Screws, #9 x 2-1/2 inch, Rust Resistant Bronze for Exterior Use, T-25 drive, Bronze, 1/4 Keg, 2500 pcs

Most important from

5310 reviews

The Hillman 967777 Premium Outdoor Wood and Deck Screws are designed specifically for outdoor projects, such as decking. These screws are crafted from steel and coated with a 4-layer epoxy bronze finish, which offers excellent rust resistance and durability, making them a strong choice for external applications. The screws are 2-1/2 inches in length, indicating they are suitable for thicker wood pieces, providing secure attachment.

An impressive feature is the self-starting tip, which claims to engage 20% faster and requires no pilot hole. This can save time and effort during installation. The design also reduces wood splitting by 75%, which is beneficial for maintaining the integrity of your materials. The T-25 Torx drive system, supported by the included bit, minimizes slippage and camout, enhancing ease of use and installation precision.

However, the product comes in a bulk package of 2500 pieces, which might be excessive for small projects. Additionally, while the screws offer a limited warranty against rust and corrosion, it's important to note that they are best used with pressure-treated wood to maximize durability.

While the flat head style is typical for a flush finish, it may require countersinking in some applications to avoid surface splitting. The screws are generally suitable for those who frequently work on outdoor wood projects and require a reliable fastening solution, particularly given their rust-resistant properties and efficient design.

Most important from

5310 reviews

Deck Plus 48412 Wood Screws #8 x 1-5/8", Tan, 5lb Box

Most important from

13636 reviews

The Deck Plus 48412 wood screws are designed specifically for outdoor decking projects, offering a good balance of durability and ease of use. Made from steel, these #8 size screws are 1-5/8 inches long, a common size for securing deck boards. They feature a tan ceramic coating with four layers, providing strong protection against rust and corrosion, which is essential for outdoor exposure.

These screws have a flat head that sits flush with the wood, creating a clean and smooth finish without protruding. Their self-drilling point and coarse threads usually eliminate the need for pre-drilling, saving time and effort during installation. The star (Torx) drive system reduces slippage and cam-out, making it easier to drive the screws in without damaging the head, and the included T25 star bit ensures you have the right tool on hand.

These screws are designed specifically for wood and exterior use, so they may not be ideal for other materials. Although the ceramic coating offers excellent corrosion resistance, it is recommended to verify compatibility with your specific deck materials. They provide a reliable, rust-resistant fastening solution that simplifies deck building or repairs for homeowners and DIY enthusiasts.

Most important from

13636 reviews

CAMO Edge Deck Screws 1-7/8" Stainless Steel (1750)

Most important from

138 reviews

The CAMO Edge Deck Screws are designed to meet specific needs for deck building, particularly in terms of concealment and durability. Made from Type 316 Stainless Steel, these screws are known for their corrosion resistance, making them a strong choice for outdoor applications where exposure to the elements is a concern. At 1-7/8 inches, these screws are suitable for typical decking thicknesses, providing a secure hold without protruding excessively.

The black exterior finish offers a sleek, subtle look that complements the idea of hiding the screws in the side of the board. This feature benefits those looking for a clean, uninterrupted appearance on their decks. The trim head style and Torx drive system provide a reliable hold and ease of installation, reducing the risk of stripping the screw head.

However, the screws being partially threaded means they may not provide as strong a grip as fully threaded options, particularly in dense or hardwood materials. The use of alloy steel, while robust, suggests that these screws might be heavier, as indicated by the product weight. This could be a consideration for projects where weight is a factor, such as in high-elevation decking. With the included quantity of 1750 pieces, these screws are ideal for large projects, covering up to 500 square feet of decking, making them cost-effective for extensive builds. These screws are best suited for those looking for a balance of aesthetics and function in their decking projects.